Laboratory testing at GRW Gebrüder Reinfurt GmbH & Co. KG yields breakthroughs in lubrication for longer life in medical applications.Lubricants tested to the extreme:

Rimpar, January 24th, 2011- As Europe’s largest manufacturer of miniature and small ball bearings GRW has recently completed detailed testing and the optimal use of lubricants for miniature and small ball bearings for dental and medical applications. Sterilization requirements push the envelope of lubrication and longer life demands under these extreme environmental conditions. Extensive laboratory tests comprising 30 lubricants from different manufacturers have yielded five resistant lubricants: polyurea-thickened greases with a mineral oil base or PAO are most suitable for use in medical products that are exposed to sterilization. These lubricants are already being used extensively for the ever increasing demands of the dental and medical markets. Field results have already produced longer life and have added considerably to our customers’ bottom line.

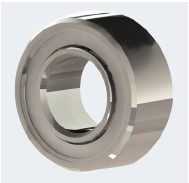

Photo 1: Dental Applications require special lubricants for optimum performance where standard lubricants do not survive.

High Speed dental applications place additional challenges to lubrication. Mandatory sterilization is very harmful to lubricants. Guidelines from the Robert-Koch-Institute for the processing of medical instruments place great demands on miniature ball bearings used in dental handpieces. Autoclave sterilization coupled with superheated steam has minimal affects on GRW’s corrosion resistant bearing and retainer materials – however, lubrication is another issue alltogether. Frequent relubrication of dental instruments with oil sprays contaminates medical devices that are used e.g. for the treatment of open wounds, and therefore which represents an unnecessary risk potential. This is why GRW places high demands on initial lubricantion with respect to surface behavior and sterilization.

GRW’s research and development staff have tested a total of 30 lubricants in the course of this study including 1,000 sterilization cycles with superheated steam. Eleven of these greases were prematurely eliminated due to functionality limiting changes e.g. water retention in the grease samples and thermal expansion during autoclaving.

Weight and optical changes, scanning electron micrographic inspections as well as infrared spectra were part of the analytical and visual test criteria for the remaining 19 lubricants. The ball bearings themselves were subjected to running noise (GPR) and starting torque behavior tests. Afterwards they were life tested on GRW’s in-house dental test stands developed specifically for these applications.

GRW’s engineers evaluated the various test results particularly with respect to high speed applications in dental turbines.

Apart from the advantages ascertained from running noise and starting torque, testing on our dedicated dental test stand also showed obvious advantages of prolonging life and subsequent contributions to our customers’ bottom line.

In addition it was recorded that any increase of starting torque, caused by viscosity changes in the lubrication, resulted in considerable heat generation within each bearing. The visual condition of the grease and the loss of mass carried less weight in our test criteria. Infrared spectroscopy and SEM-analysis served as our primary reason for any grease changes or alteration.

Photo 2: Foaming, Water Retention, Base Oil Separation: Visual observations of the lubricants tested for optimum performance by GRW.

Conclusion: The best results, taking into account all known criteria, were achieved using polyurea-thickened greases with a mineral oil base or PAO. Greases thickened with special lithium or sodium soap additives are unsuitable for autoclaving. Superheated steam readily permeates these altered greases and has a negative effect on the adhesive properties of each grease on the functional surfaces of a ball bearing.

About GRW Gebrüder Reinfurt

GRW Gebrüder Reinfurt GmbH & Co. KG, located in Rimpar near Würzburg, is Europe’s largest manufacturer of high-precision miniature and small ball bearings and is specialized in producing miniature deep-groove ball bearings made of through-hardened chrome and stainless steels. Our production capabilities comprise ball bearings with bore diameters from 1 to 25 mm and outer diameters from 3 to 40 mm in both metric and inch sizes. Our engineers not only design bearings for extreme environments but excel in helping our customers to create a bearing friendly environment to optimize performance. Among others GRW’s high precision ball bearings are used in electric motors, office machines, measurement and control devices, medical and dental equipment, high vacuum applications and aerospace. Wherever the requirements call for the highest precision, reliability and durability under the most extreme conditions, GRW bearings are not just an “added value” but a “must”.

|